MHZ2/MHLZ AIR GRIPPER SERIES PNEUMATIC CYLINDER TUBE, ALUMINIUM ALLOY CYLINDER TUBE

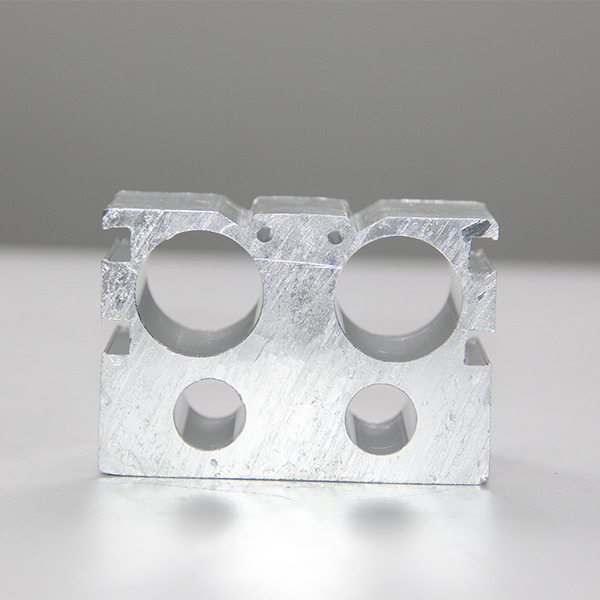

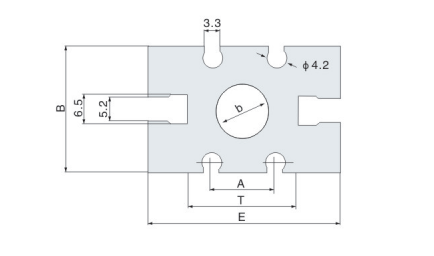

Gambar Seri MHZ2:

| NO | d | E | T | A | B | b |

| 1 | Φ10 | 23 | 12.4 | - | 16.5 | 5.5 |

| 2 | Φ15 | 30.6 | 19 | 11.6 | 23.6 | 7.5 |

| 3 | Φ20 | 42 | 24 | 14 | 27.6 | 11.5 |

| 4 | Φ25 | 52 | 29 | 18 | 33.5 | 13.5 |

| 5 | Φ32 | 60 | 38.5 | 28.6 | 40 | 13.5 |

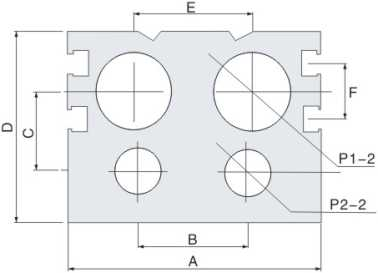

Gambar Seri MHL2:

| NO | d | P1-2 | P2-2 | A | B | C | D | E |

| 1 | 10 | 9.2 | 6.5 | 44.3 | 18.2 | 12.4 | 12.4 | 20 |

| 2 | 16 | 15.2 | 9.5 | 55 | 22.5 | 16.4 | 16.4 | 25 |

| 3 | 20 | 19.2 | 11.5 | 65 | 28.2 | 20 | 20 | 30 |

| 4 | 25 | 24.2 | 13.5 | 76 | 33.3 | 23.4 | 23.4 | 38 |

| 5 | 32 | 31.1 | 15 | 82 | 32.3 | 30 | 30 | 40 |

| 6 | 40 | 39 | 17.4 | 98 | 40.2 | 37 | 37 | 48 |

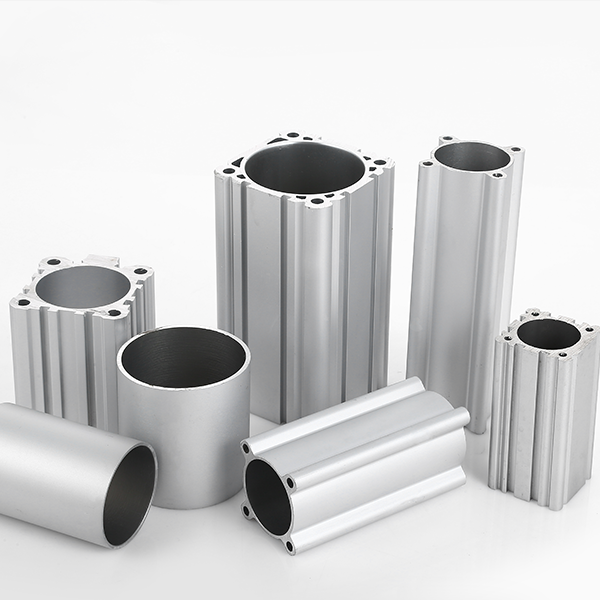

Bahan Aluminium Alloy Profil Tabung silinder pneumatik aluminium: paduan aluminium 6063 T5

Length standar kita 2000mm, yen perlu dawa liyane, please bebas kanggo ngandhani kita.

Lumahing anodized: Inner tube-15±5μm Outer tube-10±5μm

Selaras karo desain FESTO, SMC, Airtac, Chelic lsp.

Sesuai karo standar ISO 6430 ISO6431 VDMA 24562 ISO15552 etc.

Digunakake kanggo silinder standar, silinder kompak, mini silinder, Dual Rod silinder, Geser silinder, Geser Tabel silinder, Gripper etc.. Uga kanggo sawetara silinder khusus.

Komposisi kimia:

| Komposisi kimia | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Spesifikasi:

| Intensitas Tegangan (N/mm2) | Kekuwatan Ngasilake (N/mm2) | Daktilitas (%) | Kekerasan lumahing | Akurasi Diameter Internal | Kekasaran internal | Straightness | Kesalahan Kekandelan |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | <0.6 | 1/1000 | ± 1% |

Tolerance saka Aluminium Alloy Tube:

| TORLERANCE saka ALUMINIUM ALLOY TUBE | ||||||

| Ukuran Bore | TORLERANSI | |||||

| mm | H9 (mm) | H10 (mm) | H11 (mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0,052 | 0.084 | 0.13 | |||

| 25 | 0,052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0,074 | 0.12 | 0.19 | |||

| 70 | 0,074 | 0.12 | 0.19 | |||

| 80 | 0,074 | 0.12 | 0.19 | |||

| 100 | 0,087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: Apa Air Gripper?

A: Air Gripper uga disebut silinder pneumatik driji udara.

Fungsi saka silinder pneumatik Air Gripper kanggo nangkep lan Pick lan panggonan obyek ing mekanisme workpiece transfer, lan iku kanggo ngganti tangan manual kanggo entuk peran gripping otomatis.Biasane digunakake ing jalur produksi otomatis, manipulator, gripping otomatis lan peralatan mekanik otomatis liyane,

Kanthi tingkat otomatisasi sing saya tambah, silinder driji pneumatik wis dadi bagian penting saka mesin lan peralatan modern.

Q2: Kolom endi sing kudu digunakake?

A: Silinder Air Gripper utamane digunakake ing manipulator, industri mobil / robot, mesin ngecor / karet lan mesin plastik / industri alat mesin, peralatan ngirim, mesin kemasan, industri panganan, medis lan kimia, otomatisasi kantor lan industri manufaktur peralatan liyane.

Q3: Apa model ing Air Gripper (profil aluminium silinder pneumatik)?

A: SMC standar MHZ2 lan MHL2 silinder pneumatik.

Q4: Apa ukuran bolongan kanggo MHZ2?

A: ukuran bolongan duwe 10mm, 16mm, 20mm, 25mm, 32mm, 40mm.

Q5: Apa karakteristik Air Gripper?

A:

1.Kabeh struktur tumindak kaping pindho, bisa nyadari nyekel rong arah, bisa kanthi otomatis pusat, lan duwe akurasi baleni sing dhuwur.

2. Torsi grip tetep,

3. Saklar deteksi stroke non-kontak bisa diinstal ing loro-lorone Pneumatic Cylinder

4. Ana macem-macem cara instalasi lan cara sambungan,

5. Konsumsi hawa sing kurang

Q6: Kepiye babagan MHL2 Air Gripper?

A: Iku Wide Type Air Gripper MHL2.

1. Stroke dawa

2. Becik kanggo nyekel workpieces ukuran gedhe sing duwe varians dimensi

3. Piston pindho nyedhiyakake akeh gaya grip.

4. Dibangun ing mekanisme pangayoman bledug